Why derisking matters to Canada

Guest ContributorApril 15, 2014

By Dr Ian McWalter

Peter Morand's recent commentary in RE$EARCH MONEY on improving Canada's innovation performance deserves some elaboration ("Finding solutions to Canada's innovation gap," R$, February 10/14). He rightfully focused on the lack of capital to de-risk promising technologies, and on the need for Canada to nurture an ecosystem to accelerate the process of moving innovations to market.

Writing from the perspective of an organization that provides a "de-risking ecosystem," let me give an example of why this kind of activity matters.

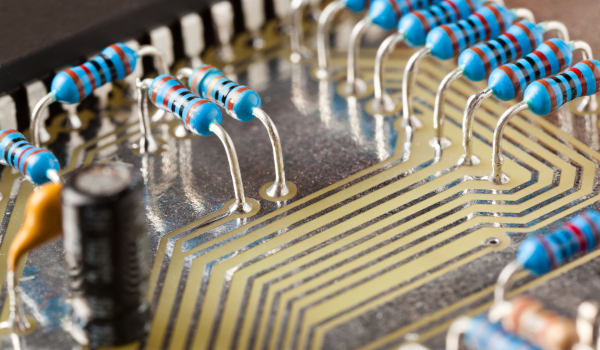

Today, silicon photonics is revolutionizing the development of a broad range of technologies in communications, computing and medicine, among others. But six years ago, the notion of miniaturizing optical components on to silicon chips was just beginning to be understood, mostly by academic researchers.

At the time, CMC Microsystems and Univ of British Columbia nanophotonics innovator Lukas Chrostowski recognized this emerging field as a good training opportunity for researchers and their students, and by 2009 CMC and the UBC had piloted and launched the world's first national, graduate-level course for designing, making and testing nanophotonic integrated circuits.

That course piqued the interest of Tera-Xion, a Canadian manufacturer of optical components and modules for the telecommunications industry. After more than a decade of producing innovative products, the company was seeing increasing interest by its customers in smaller, more integrated systems capable of handling higher volumes of data. TeraXion identified silicon photonics as the technology to meet this demand and its senior scientist, Dr Yves Painchaud, became the course's first industry participant.

Tasked with designing their own silicon-photonic chip, course participants completed intensive training on commercial-quality design tools provided through CMC, increasing the likelihood that their designs would be "scalable" to real-world manufacturing. That's de-risking.

Over the next three months, students worked independently to design and model their device. CMC engineers provided guidance and verification, making sure the students' designs ‘got it right' before final submission for fabrication. That's de-risking.

The real test of a design's integrity is to make the planned device, but doing so can be prohibitively expensive. However, through its partnership with a leading international manufacturer, CMC was able to facilitate cost-efficient fabrication of participants' designs. For TeraXion, being able to make their own chip gave them valuable insights into the potential and performance of silicon photonics, efficiently, at a reasonable cost, and earlier than anyone else.

Meanwhile, CMC's early, iterative work with researchers enabled it to develop design kits and design rule "checkers" that streamlined and automated the steps required for making silicon-based photonic circuits. Using these kits, and guided by the expertise of CMC's engineers, TeraXion was able to complete essential R&D on a new product within a year, at substantial time- and cost-savings. That's de-risking.

Today TeraXion is using its silicon photonics product design and manufacturing capabilities to develop new high-end products with the speed, size and performance that are critical to future innovation. It is a Canadian company with a global competitive advantage.

But these de-risking activities have another, equally valuable outcome. Since our pioneering course with UBC began, more than 100 individuals from 18 universities and industry have gained knowledge and experience in designing, collaborating in, and commercializing innovative silicon photonics technologies.

Many barriers to market entry are being overcome as processes become more streamlined and practitioners become more skilled in finding innovative applications for silicon photonics. That, too is derisking.

Recent events such as the Optical Society's annual conference are showing us that in silicon photonics, the global race is on. It's a race in which Canada has held a strong lead for many years — but we need to do more to stay ahead. Having the right de-risking ecosystem offers a proven model for enabling Canada to build critical mass and global leadership in the design and manufacturing of these transformative technologies.

Ian McWalter is President & CEO of CMC Microsystems.

Events For Leaders in

Science, Tech, Innovation, and Policy

Discuss and learn from those in the know at our virtual and in-person events.

See Upcoming Events

You have 1 free article remaining.

Don't miss out - start your free trial today.

Start your FREE trial Already a member? Log in

By using this website, you agree to our use of cookies. We use cookies to provide you with a great experience and to help our website run effectively in accordance with our Privacy Policy and Terms of Service.